- HOME

- About

- Products

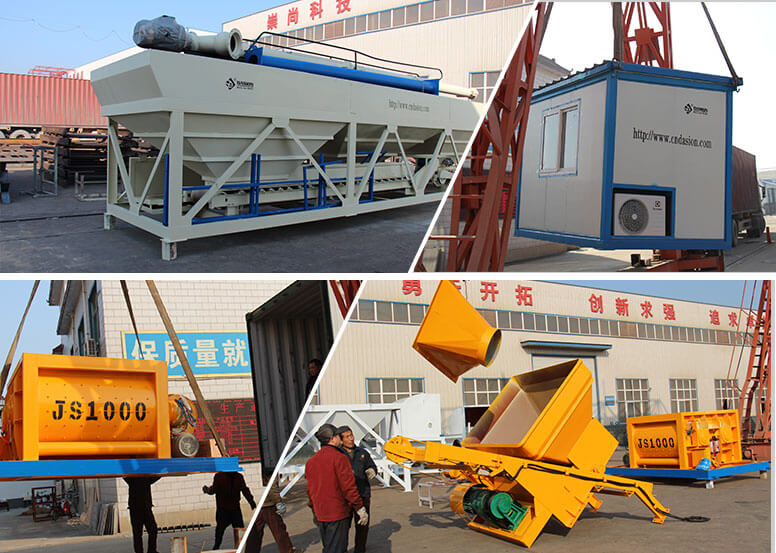

- concrete mixer

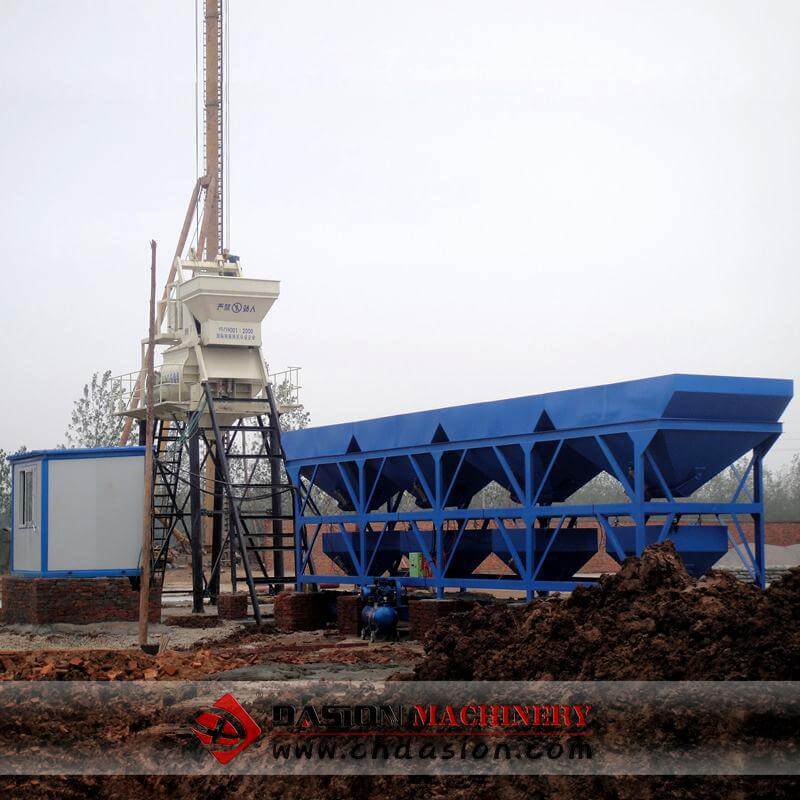

- concrete batching plant

- Bucket Concrete Batch Plant

- Belt Concrete Batching Plant

- Mobile Concrete Batching Plant

- Container Concrete Batch Plant

- HZS25 Concrete Batching Plant

- HZS35 Concrete Batching Plant

- HZS50 Concrete Batch Plant

- HZS75 Concrete Batching Plant

- HZS60 Concrete Batching Plant

- HZS90 Concrete Batching Plant

- HZS120 Concrete Batch Plant

- HZS180 Concrete Batching Plant

- WBZ Stabilized Soil Mixing Plant

- Self-loading concrete truck mixer

- concrete pump

- concrete plant optional parts

- concrete vibrator

- Panorama

- Manufacture base

- News

- AGENT

- case

- Contact